LARGE, FAST ABS 3D PRINTERS

ABS (acrylonitrile-butadiene-styrene) is fantastic thermoplastic for 3D printing and demonstrates very good engineering-grade characteristics. You’ll find ABS to be strong, providing impact, heat and abrasion resistance. ABS is somewhat chemical resistant. Its surface is hard, the material pretty rigid and provides good tensile strength and dimensional stability. ABS in filament form, compared to other thermoplastics, is quite inexpensive and can be purchased from high quality suppliers from $20.00 to $30.00 USD per Kilogram.

ABS is one of many 3D printing materials that fall in the category of high-temperature materials (requiring printing at temperatures hotter than room temperature) which pose special challenges for consumer/low-cost 3D printers. As a result, from a consumer or hobbyist perspective, certain materials like ABS have an undeserved reputation as not well suited for 3D printing.

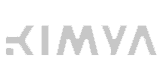

ABS 3D Printed Welding Clamp

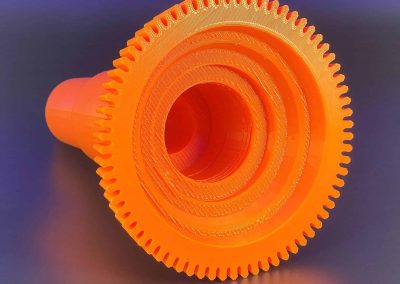

The New EDGE High-Performance 3D Printer

Optimized For 3D Printing Higher-Temperature Materials Including ABS

FUSION3’S 3D PRINTERS ARE EXPRESSLY DESIGNED TO PRINT HIGHER-STRENGTH / HIGHER TEMPERATURE MATERIALS LIKE ABS FOR EXCEPTIONAL RESULTS

Enclosed, Passively Heated Print Chamber For Optimal Results

ABS Parts Must Stay Warm For Proper Layer Adhesion

- The enclosure passively retains heat given off by the heated print bed and the print head, raising the ambient temperature of the build chamber and further reducing thermal stress.

- The enclosure eliminates the influence of air drafts, like downdrafts from air conditioning which could rapidly cool the part.

All plastics have a shrinkage rate between 0.3 – 4% during the cooling process. If the surrounding temperature is not properly controlled, this shrinkage process can cause part deformations, warping, and compromise the strength and integrity of the final part or product.

Example of An ABS Part with Poor Layer Adhesion Due to Lack of Heat

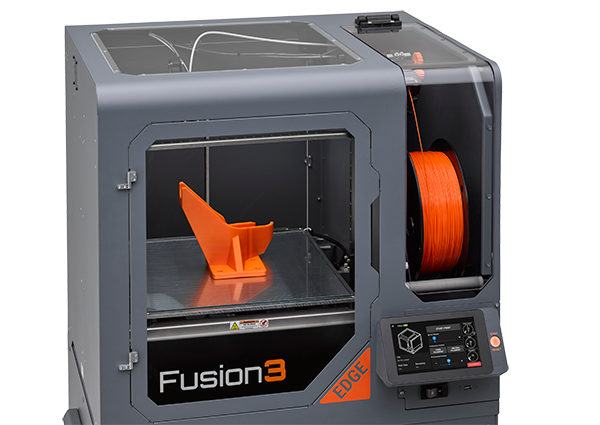

Precision Print Heads For High-Temperature, High-Flow 3D Printing

Successful ABS 3D Prints Require Your Print Head To Melt Quickly And Keep Up

Fusion3’s focus on speed and print quality has required us to use only the most reliable, high-flow heads that allow for quick heating of the material at sustained, high temperatures to maintain a high rate of material flow.

Thanks to our proprietary ANVIL print head, the Fusion3 EDGE meets these exacting requirements. With its surgical steel print tubes and higher performance PT1000 temperature sensor and 65W heater cartridges, the EDGE 3D printer is able to heat quickly and maintain the fastest flow rates of any 3D printer Fusion3 has ever built, maintaining consistent high heat, ensuring rapid extrusion and creating strong bonds between the layers. EDGE is designed to reach temperatures up to 320°C (608°F) on the printhead and 140°C (284°F) on the build plate, greatly expanding the possible applications of 3D printed products and parts.

Fusion3’s Precision ANVIL Print Head

EDGE comes standard with a glass build plate, unlike other hobbyist printers that may use weaker materials, that is placed on a 1/4″ aluminum tool plate that can withstand extreme temperatures. Fusion3 also carries a magnetic verison of the tool plate that allows for different 3rd party 3D printing surfaces to be installed, including PEI, Garolite, Polypropylene and BuildTak, depending on your specific needs.

High Power, Multi-Zone Bed Heaters

ABS parts require a hot print bed to avoid warping.

Fusion3’s 3D printers have always used high-power, multi-zone print beds. This technology breaks the print surface into multiple, discrete zones with different power densities, keeping the entire Fusion3 3D printer’s surface at the same temperature. This helps prevent undesirable cooling of the 3D printed ABS part and warping, to ensure properly designed parts.

Fusion3’s high-temperature print beds allow the printed material to stick better to the build plate, creating a stable surface that eliminates slippage or movement. First layer print adhesion to the build plate is essential to creating a strong and durable part or product, especially with ABS and other thermoplastics since they have a higher glass transition temperature. The glass material used in the print bed also allows for easy removal of the cooled down print, enabling it to be lifted off without removal tools.

Infrared Image of the Fusion3 EDGE’s Multizone Heated Bed

There are hundreds of ABS 3D printer filaments on the market, many from overseas/low-cost markets. However it is worth spending a few more dollars per kilogram for filament from a high-quality domestic supplier who focuses on precision and consistency of extrusion.

Over 27 Different Generic & Speciality ABS 3D Printer Filaments, Tested & Certified For Fusion3 3D Printers

We have tested and certified a wide variety of ABS materials from leading manufacturers for use in our 3D printers.

Fusion3 receives requests from both customers and manufacturers to test new materials as they arrive on the market. Should they pass our rigorous testing process, we provide optimized print settings to all our customers within our F3Slic3r 3D printing software.