How to Run Calibration Tests on Fusion3 Printers

Fusion3’s customer support team deals with a wide range of issues daily. One topic we see come up regularly is folks running “calibration” tests, “benchmark prints,” or related, and being confused or upset with the results they get on their Fusion3 printers.

Our goal with this blog post is to explain why these tests are poorly suited for our equipment, and why they don’t provide useful information on how to improve your print results. We’ll also suggest some common fixes and alternative approaches so you can get the information you’re after.

Why Common Hobbyist Calibration Tests Do Not Work on Fusion3 Printers

First, let’s discuss some common calibration and test prints we see people run, and encounter issues with:

- 3DBenchy

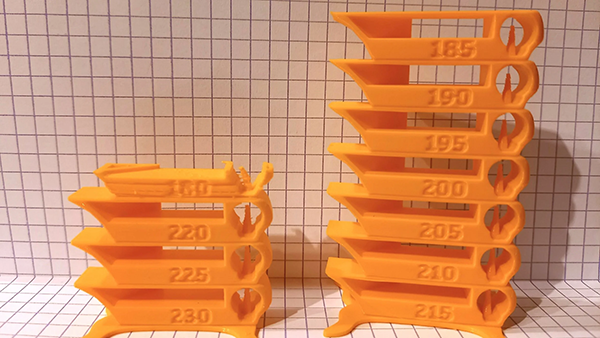

- Temperature towers

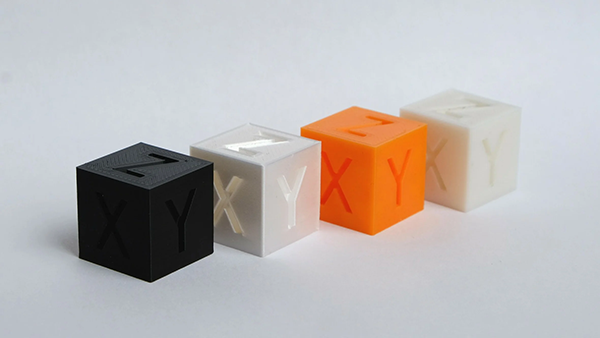

- 10mm or 20mm calibration cubes, run one at a time

Taken from https://en.wikipedia.org/wiki/3DBenchy

Why Are These Tests Poorly Suited to Fusion3 Printers?

Our printers are designed and optimized for printing large parts quickly, out of high-temperature materials such as ABS, ASA, and PC. This design and optimization covers both the design and construction of the printer hardware, AND the slicer profiles we publish.

Issues with Thermal Soak

One side effect of this optimization is that printing small parts on Fusion3 printers can cause a problem that is not commonly found on hobbyist/consumer printers: thermal soak. This is when a print is so small and printed so fast, the layer you just printed does not have time to cool down and solidify before the next layer is printed on top of it. This is often a cumulative or compounding problem: the more layers it goes on for, the worse the problem becomes.

Thermal soak results in edge curling, ugly and blobby misshapen corners, curling or deformed overhangs, and generally misshapen prints. The compounding nature of the problem means a print that just looks a little funny on one layer may look unrecognizable 20 or 30 layers later.

One thing all of the calibration/test prints we mentioned have in common is they are small! This means they all have major problems with thermal soak. This thermal soak issue often makes it impossible to use these prints for their intended purpose (improving your print quality), since any “signal” of changes to make is lost in the “noise” of thermal soak issues. Or worse, you spend time chasing a problem that shows up in your calibration print, that would not actually show up in your real (larger) print.

Fusion3 Printers’ Unique Design

Fusion3 printers work differently than hobbyist printers. Our equipment runs hotter, runs faster, and has an enclosure. So while our equipment is FDM/FFF, as are many hobbyist printers, our approach to energy management in the printed part is dramatically different. This means the approaches, rules of thumb, normal settings, etc. that hobbyist printers/users use are not necessarily correct for our equipment, even if you’re printing the same material (or the same print) on both. And common quality/troubleshooting tests from the hobbyist world don’t work as well. AND, if they do “work,” the results you get and the correct corrective actions to take, may be different than what you’d do in the hobbyist world.

How to Run Common Calibration Prints on Fusion3 Printers

If you want to run these common calibration test prints and have them stand a chance of working well and providing meaningful information, here are some tips:

- Run them in higher temperature materials (ABS, ASA, etc instead of PLA)

- Print two or more of them at once, spaced apart 50-100mm

- Start on the “standard” or “default” quality setting. “High” quality presets don’t always mean your part is going to look better

- Pay attention to how they are oriented on the bed – orient overhangs towards the blower side

How Should I Solve Print Issues Without Calibration Prints?

We understand that without these calibration prints, you may feel a bit lost on how to tune your print settings. Here are some helpful tips for solving print quality issues with your Fusion3 printer:

- For printing temperatures, use our slicer-supplied settings and IGNORE the manufacturer’s settings (on the spool or on their website)

- If you encounter a situation that you think will be solved by printing a temperature tower and adjusting print temperatures, STOP and get in touch with us. 90% odds it’s not the print head temperature causing your problem

- Some print quality guides online are OK. They are good for giving you the direction to look at but don’t blindly apply all their recommendations

- Check out this link for troubleshooting steps: https://www.simplify3d.com/resources/print-quality-troubleshooting/

- When in doubt, contact our support team and let us help. We know our equipment in and out and have been doing this for a decade. Odds are we have seen something like your situation before

Part of what you pay for with your Fusion3 printer is our expertise and experience to help you get the results you need. Don’t feel like you need to figure out everything by yourself. And in 99% of cases, we’ve already done the work that these calibration tests are designed to help with. At Fusion3, we take pride in providing our customers with high-quality 3D printers to meet every application and integrate seamlessly into your process.

For more information on our 3D printers and how we can address your business 3D printing needs, please Contact us today!